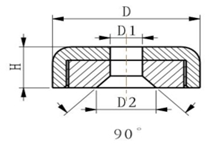

A-Series----Pot Magnets with Countersunk Borehole

Detail Information

SNA(Stamping - NdFeB - Countersunk Borehole)

LNA(LatheMachining - NdFeB - Countersunk Borehole)

Pot magnets are special magnets which, especially the bigger ones, are used in the industry as industrial magnets. The magnetic core of pot magnets is made of neodymium and is sunk in a steel pot in order to intensify the adhesive force of the magnet. That is why they are called "pot" magnets. Often they have a centered borehole and countersink which makes it possible to screw them firmly to the primer. Please consider that the indicated adhesive force of the pot magnets is measured perpendicularly to the primer. Maybe a stronger magnet is necessary for a fixation on the wall. Please contact us in this case for an individual advise.

We offer pot magnets with different adhesive forces. Our strongest pot magnet has an adhesive force of 180kg! These supermagnets are perfectly suited to be screwed into the primer. Even the smaller pot magnets are amazingly strong. Therefore they are often used as mounting magnets or strong adhesive magnets. They are e.g. used for model making, booth construction or metal construction. They can also be used to grab objects.

Important advice concerning magnets: Please consider that many of our magnets have a strong adhesive force. They can affect the function of electric devices or even destroy them. Even the small pot magnets must be kept out of the reach of children because there is always a risk of injury. People with pacemaker or hearing device should also avoid magnets.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Review

- Loading...

Please send your message to us

- Name

- Phone

- *Title

- *Content