Hard Ferrite Magnets

Invented by Tokyo Institutes of Technology in 1933, Ferrite magnet, as one of the most common permanent magnetic materials, is a type of metallic oxides with ferromagnetism. Ferrite possesses high dielectric property and way higher electric resistance than other metal or magnetic alloy. Thanks to these advantages, ferrite magnets are widely applied in high-frequency and weak current applications, which, reversely, are excluded by low-frequency and strong current areas.

Ferrite magnets are divided into 3types: hard ferrite magnets, soft ferrite magnets and gyromagnetic ferrite.

By magnetic property and application, ferrite magnets come in 5 types: soft ferrite, hard ferrite, gyromagnetic ferrite, rectangular hysteresis ferrite and piezo-magnetic ferrite.

The most common hard ferrites are:

Strontium ferrite, SrFe12O19 (SrO•6Fe2O3), used in small electric motors, micro-wave devices, recording media, magneto-optic media, telecommunication and electronic industry.

Barium ferrite, BaFe12O19 (BaO•6Fe2O3), a common material for permanent magnet applications. Barium ferrites are robust ceramics that are generally stable to moisture and corrosion-resistant. They are used in e.g. loudspeaker magnets and as a medium for magnetic recording, e.g. on magnetic stripe cards.

Cobalt ferrite, CoFe2O4 (CoO•Fe2O3), used in some media for magnetic recording.

Hard Ferrite magnets have a high coercivity and high remanence after magnetization. Iron oxide and barium or strontium carbonate are used in manufacturing of hard ferrite magnets. The high coercivity means the materials are very resistant to becoming demagnetized, an essential characteristic for a permanent magnet. They also have high magnetic permeability.

These so-called ceramic magnets are cheap, and are widely used in household products such as refrigerator magnets. The maximum magnetic field B is about 0.35 tesla and the magnetic field strength H is about 30 to 160 kiloampere turns per meter (400 to 2000 oersteds). The density of ferrite magnets is about 5 g/cm3.

Pros:

1. least expensive material compared to alnico magnets or rare earth magnets

2. high intrinsic coercive force

3. corrosion resistance

Cons:

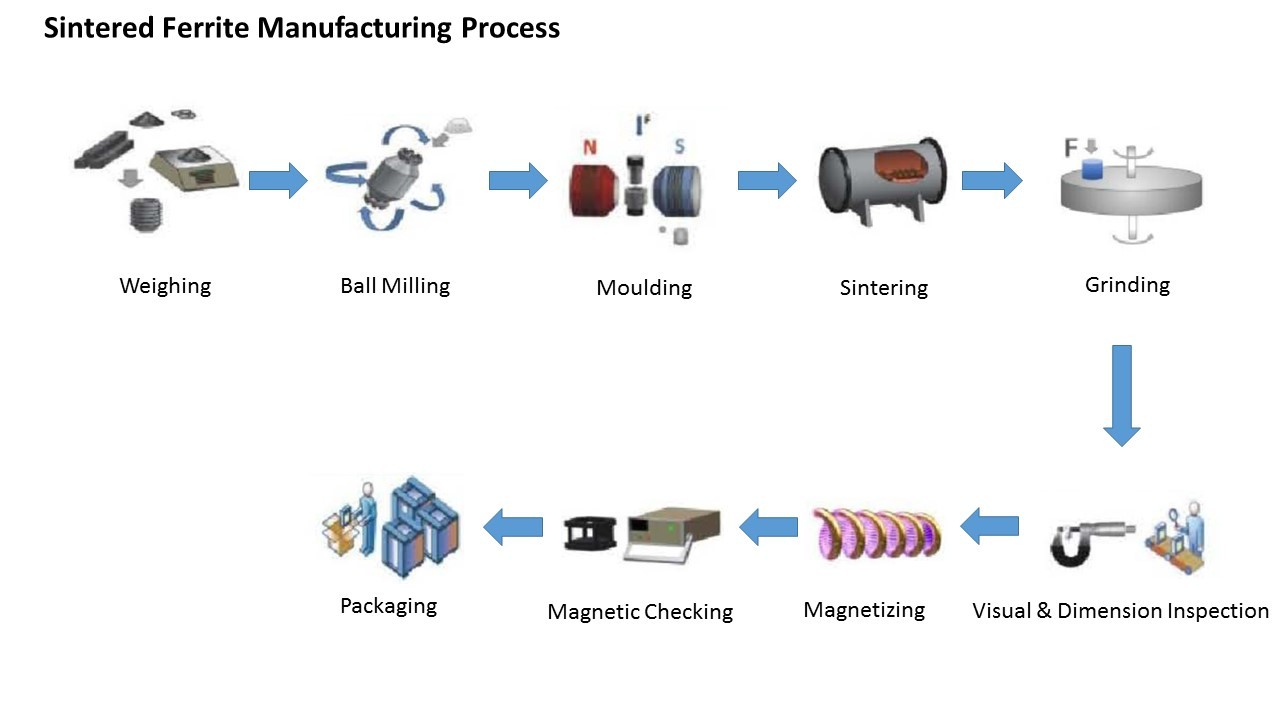

1. Hard ferrite magnets (Barium ferrite and strontium ferrite), are manufactured in power metallurgy process.

2. Maximum working temperature is as high as 250℃, hard but crispy.

Hard ferrite magnets can be machined with diamond grinding wheel and molded with alloy steel dies.

Soft ferrite magnets have low Hc (coercive force) and can be re-magnetized repeatedly.

Magnetism shall vanish or be mostly lost when the external electric field is removed.

Ferrite magnets are used as permanent magnetic component within assorted panels, DC brushless motors, permanent magnet DC motors, separators (separate ferrous matters from non-ferrous matters), magnetic assemblies (designed for lifting, holding, retrieving etc), generators, telephones, loudspeakers, televisions, computer memories, microwave components in radar, telecommunication, navigation, telemetry, etc.

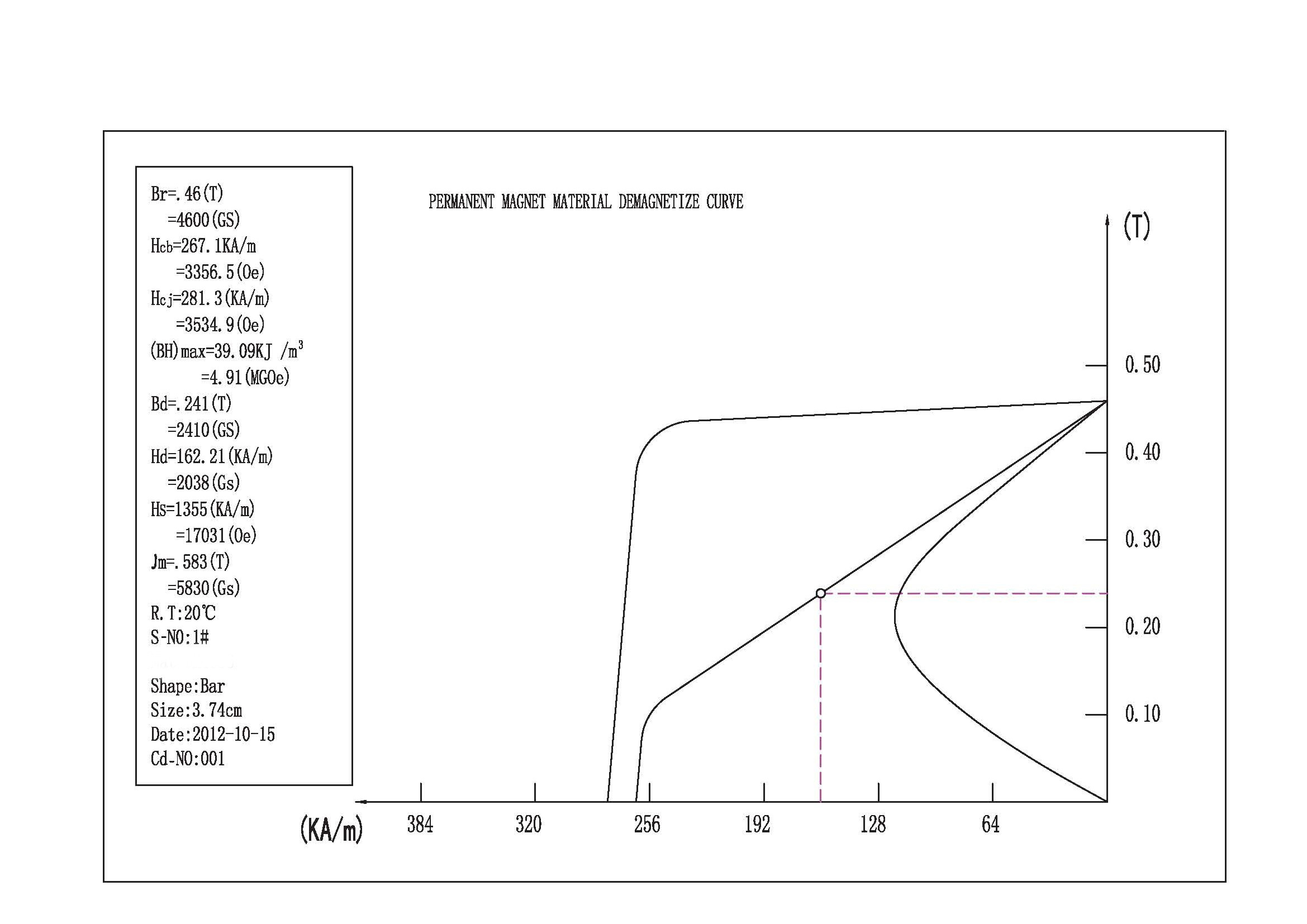

Sintered Hard Ferrite Demagnetisation Curve (Y40)

- Loading...

- Name

- Phone

- *Title

- *Content