How To Optimize Magnet Cost?

An enterprise is

a profit-oriented organization, and it is facing unprecedented operating

pressures currently. These pressures come from the demands of business growth,

accelerated innovation, and continuous improvement in productivity, as well as

market competition, globalization trends, the pace of information technology

and business change is accelerating, also from the need to reduce costs.

The reduction in

cost means the enlargement of profit margins, and it will have stronger

competitiveness in the market. Here we discuss how to reduce costs healthily

and effectively from the aspects of management improvement, process

optimization, technological innovation, and manufacturing innovation.

Most of

manufacturing enterprises have relatively rapid initial development, rapid

business expansion, and rapid expansion of production capacity, but actual

profits are gradually shrinking, mainly due to the lack of effective management.

Although most of them have applied for quality certificates, ISO9001, etc. the

actual operation of the system is not effective, eventually turned into a piece

of paper. The effective implementation of the quality system is conducive to

controlling and reducing costs, helping companies seek ways to improve product

quality. The management can also grasp the problems in quality management, and

at the same time can broaden the cost management channels. In addition to the

effective operation of the system, the use of quality tools, such as SPC, MSA,

FMEA, APQP, PPAP, etc. can help companies in the manufacturing process to help

us find the variation in the process, and take corresponding measures to

restore production to normal, to reduce the defects caused by mutation, thereby

reducing the cost of poor quality

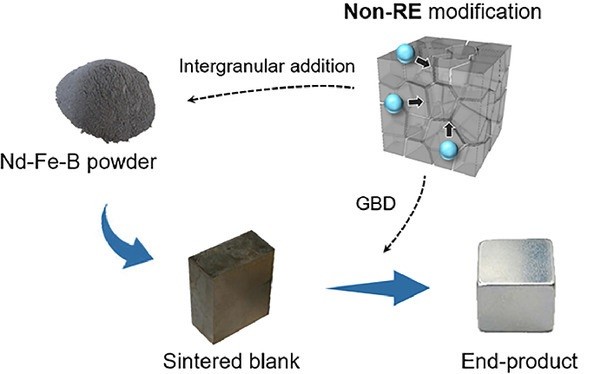

Technological

innovation is of great significance to the production process of products. It

can not only greatly improve the production efficiency of enterprises, but also

bring about cost reduction and win opportunities in market competition. For

example, the current permanent magnet motors used in new energy vehicles need

to use high temperature resistant neodymium iron boron magnets. During the

manufacturing process of such magnets, a certain proportion of heavy rare earth

element Dy needs to be added to the formula, which greatly increases the cost

of the magnet. With the manufacturing innovation of the magnet technology, the

grain boundary diffusion technology not only meets the performance requirements

of the magnet, but also greatly reduces the amount of heavy rare earth used,

resulting in a substantial cost reduction.

Nowadays, the

highest cost is labor cost. In the six major factors that affect quality,

human, machine, material, method, environment, and measurement, the process

variation is caused by human factors, and the probability of causing defects is

the highest. In the manufacturing inspection process, people often make

mistakes due to fatigue, and the efficiency of labor is also a major factor

that restricts productivity. Automation equipment is a good solution. The

introduction and use of automation equipment can greatly improve production

efficiency. For example, in the magnet manufacturing process, one automation

equipment can complete the four processes of

identification-magnetization-inspection-packaging together. The efficiency is

many times that of manual work, and it is not easy to make mistakes.