Commonly Used Soft Magnetic Shielding Materials for Wireless Charging

Introduction

With the rapid development of electronic products such as mobile phones and electronic watches, wireless charging, as a safe, fashionable, and convenient new charging method, has become more and more popular among consumers. Although wireless charging is mainly used in low-power products now, in the future, wireless charging technology will be widely used in cars, computers, and other high-power products.

All electronic devices that can use wireless charging have power receivers. For example, these smart phones are called "Qi-compatible". To take advantage of wireless charging technology, you need a Qi-compatible device.

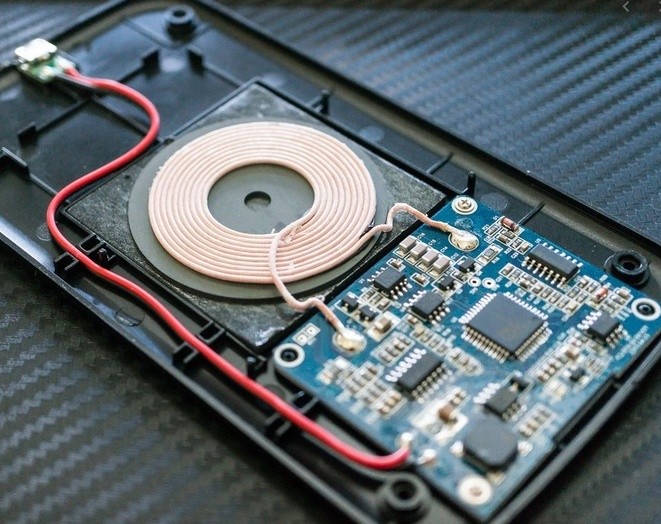

Wireless charging consists of a transmitter and a receiver. The structure is similar to a transformer. This article will mainly introduce the selection of soft magnetic shielding materials for wireless charging transmitter and its function:

1. The Material of Soft Magnetic Shielding Used in Wireless Charging

2. The Principle of Wireless Charging EMI Shielding Tape

3. Comparison of Nanocrystalline and Ferrite Magnetic Shielding Tape

4. The Requirements of Wireless Charging Transmitter for Soft Magnetic Ferrite Products

5. The Role of Soft Magnetic Shielding Tape in Wireless Charging

1. The Material of Soft Magnetic Shielding Used in Wireless Charging

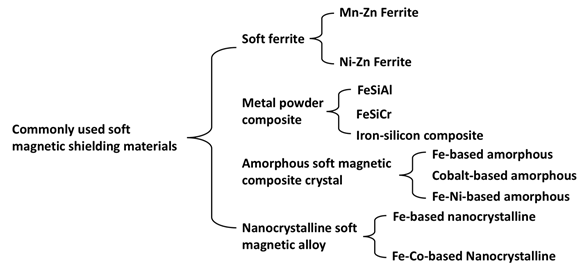

The transmitter and receiver in wireless charging are composed of coils and magnetic materials. There are different choices of magnetic materials, such as ferrite, amorphous, nanocrystalline, etc., as shown in the following figure:

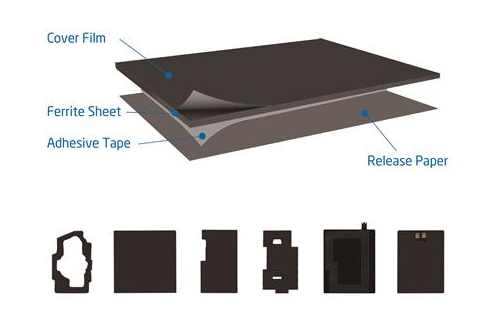

Soft magnetic products are used as magnetic shielding tapes in wireless charging, whose main function is to enhance the induced magnetic field and shield coil interference. Both of the wireless charging transmitter and receiver will use soft ferrite products. At present, most of the transmitters of wireless charging use soft ferrite. As the main components, soft ferrite products are widely used in wireless technology. Its material and shape are decisive for the conversion efficiency and electromagnetic compatibility of wireless charging.

2.The Principle of Wireless Charging EMI Shielding Tape

In mobile devices such as smart phones that are suitable for wireless charging, the receiving coil and ferrite magnetic shielding tapes mounted on it are required to be as thin as possible. However, the characteristics and thickness of magnetic materials require careful design.This is because if the magnetic sheet is too thin, it will cause magnetic saturation problems. If magnetic saturation occurs, the inductance of the coil will suddenly decrease, which may cause obstacles to the wireless charging process. A wireless charger refers to a device that uses the principle of electromagnetic wave induction for charging. There is a coil at the transmitter and receiving ends. The transmitter side coil is connected to a wired power supply to generate electromagnetic signals, and the receiving end coil induces the electromagnetic signals at the transmitter to generate current to charge the battery. The magnetic shielding tapes attached to the transmitting end antenna can enhance the magnetic field strength of the coil, and at the same time has a higher magnetic convergence effect. Placing a magnetic shielding tape on the receiving end antenna prevents the attenuation and interference of the metal conductor to the magnetic field, and plays a role of metal shielding to prevent energy waste, so as to improve charging efficiency. The role of soft magnetic shielding tape in wireless charging will be explained in more detail below.

3. Comparison of Nanocrystalline and Ferrite Magnetic Shielding Tape.

According to the experimental simulation of the real scene, the comparison test was carried out under the same conditions, and the charging efficiency was compared by using nanocrystalline magnetic sheets of different thicknesses and ferrites of different permeability and thickness. As the thickness increases, the charging efficiency continues to improve, but the thickness of the nanocrystalline is not the thicker, the better, and it is basically saturated at 0.1 mm. Therefore, when designing the wireless charging module, the nanocrystalline magnetic sheet does not need to be too thick, which will increase material costs. The regular of ferrite is similar to that of nanocrystalline. The higher the magnetic permeability, the higher the charging efficiency, the thicker the thickness and the higher the charging efficiency. However, under the same charging efficiency, the nanocrystalline magnetic sheet is only half as thick as ferrite.

Generally, the ferrite is the best soft magnetic material for NFC (near field communication). Because at high frequencies, the loss of nanocrystals is much greater than ferrite. Compared with nanocrystalline, the cost of ferrite is much lower and has cost advantages. In addition, ferrite has the advantage of mass production, because ferrite is a traditional material with very large production capacity.

4. The Requirements of Wireless Charging Transmitter for Soft Magnetic

Ferrite Products

According to the receiving end placement method, the wireless charging transmitter is divided into fixed position type, single coil free position type and multi coil free position type. These transmitters have different requirements for ferrite products.

4.1 Fixed Position Type

Fixed-position chargers use neodymium-iron-boron permanent magnets for positioning. The terminal device needs to be placed in a fixed position to charge and maximize the charging efficiency. The Qi standard stipulates that this type of design works at 110 to 205 kHz. The fixed position charger has a higher resonance frequency, and Ni-Zn ferrite sheet is generally used as a magnetic shielding tape.

4.2 Single Coil Free Position Type

The internal coil of the single-coil free-position charging device is equipped with a drive device, which can be moved in the plane by automatically detecting the placement position of the terminal device, and move the coil to this position to make the position of the coil consistent with the terminal receiving position. In order to achieve charging and improve charging efficiency. This type of design allows the terminal to be placed on the anyplace of charging board for charging. The Qi standard stipulates that the operating frequency of this type of charger is 140 kHz, because the coil needs to be moved, the magnetic shielding tape is required to have a relatively high reliability, so the magnetic shielding tape generally uses flexible magnetic sheets made by casting process.

4.3 Multi Coil Free Position Type

Multi-coil free-position charger can charge multiple terminals simultaneously. It is lined with coils that cover most of the charging base. Thus, the terminal can be placed more freely on the charging seat, and the charger will automatically select several coils that can transmit efficiently for power supply. According to the Qi standard, the working frequency of multi-coil free-position charger is 105~113 kHz, and Mn-Zn ferrite material is generally used for magnetic shielding tape.

5. The Role of Soft Magnetic Shielding Tape in Wireless Charging

5.1 Magnetic permeability and resistance reduction

Improve the coupling coefficient, improve the efficiency of magnetoelectric conversion, use fewer turns to achieve a higher inductance coil, reduce coil resistance, and reduce efficiency reduction caused by heating (the more turns, the higher the resistance). The operating principle of the QI wireless charging standard is electromagnetic induction. When the primary coil (wireless charging transmitter) is working, it will generate an interactive magnetic field, both the direction and the strength of which change constantly, and the magnetism of the primary coil needs to be guided in order to maximize the amount of magnetic energy emitted by the primary coil and received by the secondary coil (the wireless charging receiver).

After adding magnetic shielding tapes at the receiver, the magnetic lines of force significantly converge, but without a magnetic barrier to guide, the magnetic lines of force are relatively scattered. The magnetic shielding tapes at the receiver function as a magnetism guide, providing a magnetic field line loop for the magnetic field at the transmitter, so as to converge the magnetic field acted on the coil at the receiver as much as possible to achieve the maximum power generation efficiency.

5.2 Magnetic Block

The magnetic shielding tape should not only be able to effectively conduct magnetism, but also play a role in blocking magnetism. Why block the magnetism? We know that when the changing magnetic field encounters a metal or other conductor, if the metal is a closed wire, current will be generated, and if the metal is a open wire, especially a whole piece of metal, an eddy current effect will occur. The magnetic shielding tape can provide a low-impedance path for magnetic flux, reduce the magnetic field lines emitted outward, reduce the impact on surrounding metal objects, and prevent eddy currents and signal interference.

5.3 Heat Dissipation

The magnetic field acts on the inductor coil to generate high-frequency current. During this process, the coil itself will also generate heat. If this heat is not effectively dissipated, it will accumulate. Sometimes we feel very hot during wireless charging. Generally, it is caused by the heating of the inductance coil or the heating of the circuit board. The soft magnetic shielding tape will help the wireless charger to dissipate the heat.