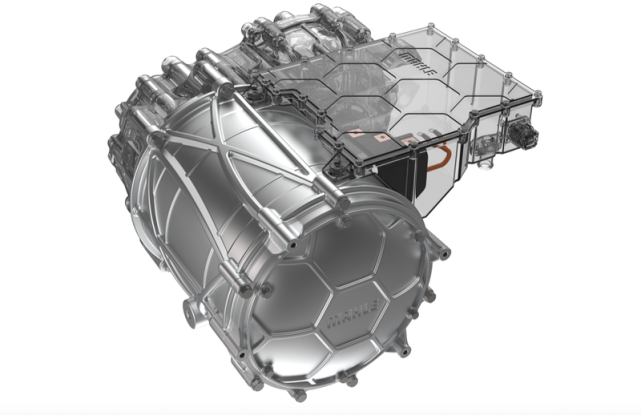

MAHLE develops highly efficient magnet-free electric motor

MAHLE develops highly efficient

magnet-free electric motor

MAHLE is currently developing a new kind of

magnet-free electric motor that does not require rare earth elements. This not

only makes production more environmentally compatible, but also brings

advantages in terms of costs and resource security. The central feature of the

new motor is the inductive and thus contactless power transmission—this allows

the motor to operate wear-free and particularly efficiently at high speeds. The

efficiency is above 95% at almost all operating points—a level that previously

has only been achieved by Formula E racing cars. MAHLE has thus succeeded in

combining the strengths of various electric motor concepts in one product. This

new development is easily scalable, so it can be used in anything from

subcompacts through commercial vehicles.

“With our new electric motor, we’re living

up to our responsibility as a sustainably operating company,” says Michael

Frick, Chairman of the MAHLE Management Board (ad interim) and CFO. “Dispensing

with magnets and therefore the use of rare earth elements offers great

potential not only from a geopolitical perspective but also with regard to the

responsible use of nature and resources.”

“Our magnet-free motor can certainly be described as a breakthrough, because it provides several advantages that have not yet been combined in a product of this type,” says Dr. Martin Berger, Vice President Corporate Research and Advanced Engineering at MAHLE. “As a result, we can offer our customers a product with outstanding efficiency at a comparatively low cost.”

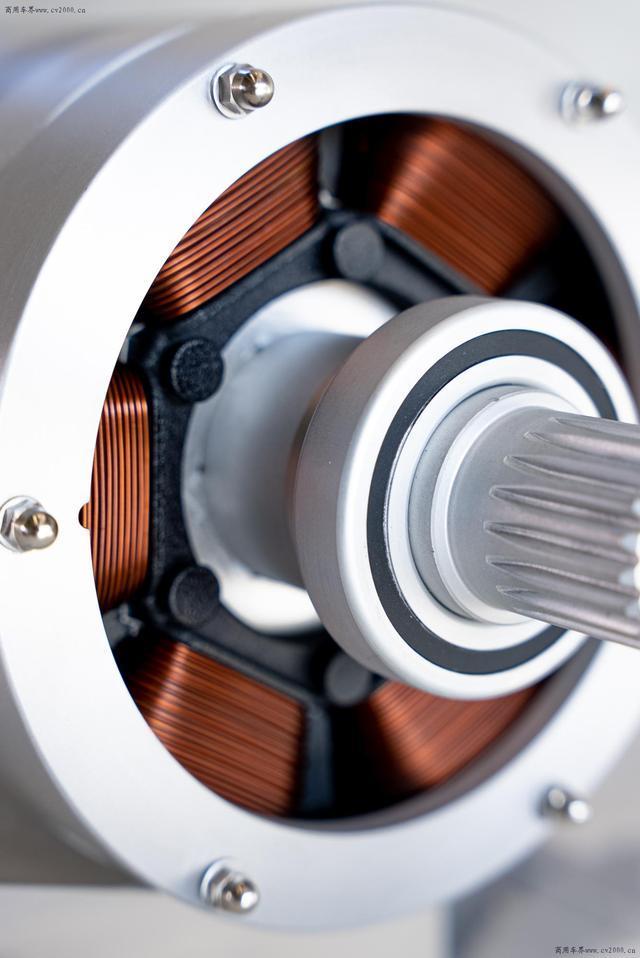

The new traction motor from MAHLE is highly

efficient—at almost all operating points—and really demonstrates these

advantages in segments where vehicles are mostly operated in real road traffic.

The new electric motor is also characterized by a high degree of

durability, because the necessary transmission of electrical currents between

the rotating and stationary parts inside the motor takes place without contact

and is therefore wear-free. This makes the engine maintenance-free and suitable

for a wide range of applications.

During its development, MAHLE uses an

innovative simulation process in which various motor designs are adjusted along

different parameters until an optimum is found. This approach is significantly

faster and cheaper than conventional processes. In this way, MAHLE is helping

to quickly create the necessary technical conditions in order to advance

e-mobility in a sustainable manner worldwide.