Aluminium and Aluminium Alloys

About Aluminum

Aluminum is an excellent "pretender".As an active metal element, it is easy to chemically react with other substances, so it can be hidden in various compounds.Most aluminum elements exist in the form of compounds, which can be formed, including rubies. Most aluminum elements exist in the form of compounds, which can be formed, including rubies. There are more than 270 kinds of minerals or rocks including jadeite.

Aluminum is an excellent "pretender".As an active metal element, it is easy to chemically react with other substances, so it can be hidden in various compounds.Most aluminum elements exist in the form of compounds, which can be formed, including rubies. Most aluminum elements exist in the form of compounds, which can be formed, including rubies. There are more than 270 kinds of minerals or rocks including jadeite.

History of aluminium

Aluminium metal is very rare in native form, and the process to refine it from ores is complex, so for most of human history, it was unknown. However, the compound alum has been known since the 5th century BCE and was used extensively by the ancients for dyeing. During the Middle Ages, its use for dyeing made it a commodity of international commerce. Renaissance scientists believed that alum was a salt of a new earth; during the Age of Enlightenment, it was established that this earth, alumina, was an oxide of a new metal. The Discovery of this metal was announced in 1825 by Danish physicist Hans Christian Ørsted, whose work was extended by German chemist Friedrich Wöhler.

Aluminium was difficult to refine and thus uncommon in actual usage. Soon after its discovery, the price of aluminium exceeded that of gold. It was only reduced after the initiation of the first industrial production by French chemist Henri Étienne Sainte-Claire Deville in 1856.In those days, chemists did not know how to separate this unknown metal from vitriol.

It was not until 1825 that Danish chemists Hans and Oster finally found a chemical method for separating aluminum, but this method was difficult to operate and the separation yield was very low.Later, German chemist Friedrich Weiler improved on this basis and developed a more efficient method. In 1845, he isolated enough aluminum to study the basic properties of this metal.

Aluminium metal is very rare in native form, and the process to refine it from ores is complex, so for most of human history, it was unknown. However, the compound alum has been known since the 5th century BCE and was used extensively by the ancients for dyeing. During the Middle Ages, its use for dyeing made it a commodity of international commerce. Renaissance scientists believed that alum was a salt of a new earth; during the Age of Enlightenment, it was established that this earth, alumina, was an oxide of a new metal. The Discovery of this metal was announced in 1825 by Danish physicist Hans Christian Ørsted, whose work was extended by German chemist Friedrich Wöhler.

Aluminium was difficult to refine and thus uncommon in actual usage. Soon after its discovery, the price of aluminium exceeded that of gold. It was only reduced after the initiation of the first industrial production by French chemist Henri Étienne Sainte-Claire Deville in 1856.In those days, chemists did not know how to separate this unknown metal from vitriol.

It was not until 1825 that Danish chemists Hans and Oster finally found a chemical method for separating aluminum, but this method was difficult to operate and the separation yield was very low.Later, German chemist Friedrich Weiler improved on this basis and developed a more efficient method. In 1845, he isolated enough aluminum to study the basic properties of this metal.

People's exploration of aluminum began with the study of alum in the 18th century.Alum is a general term for a class of compounds with similar properties, and the common alum in life is one of them.

As early as ancient Greece and Rome, people began to use alum. At that time, people used alum to stop bleeding, or as a dye to dye clothes. Research on alum showed that it contained an unknown element.

Bauxite Mining

The mining of bauxite is the first step in aluminium production.

At 8% of the earth’s crust, aluminium is the third most abundant element in nature.

The ore from which aluminium is produced is bauxite. Disregarding various quality grades, bauxite reserve estimates indicate adequate supply for at least 400 years. More than 130 million tonnes of bauxite are mined each year, the major deposits being in the tropics and sub-tropics. Bauxite is currently being extracted in Australia, Central and South America (Jamaica, Brazil, Surinam, Venezuela, and Guyana), Africa (Guinea), Asia (India, China), CIS, and parts of Europe (Greece and Hungary). In many of these regions, bauxite extraction is the only valuable natural resource.

Aluminum Application in Industries and Daily Life

Aluminum is the 3rd most plentiful metal in the Earth’s crust and the third most plentiful component total.

No other metal can compare to Aluminum when it concerns its variety of uses. Some uses of aluminum may not be instantly apparent; for example, did you know aluminum is utilized in the manufacturing of glass?

Aluminum is exceptionally popular due to the fact that it functions below:

Lightweight

Strong

Resistant to rust

Durable

Ductile

Malleable

Conductive

Odorless

Aluminum is utilized in transportation because of its unbeatable strength to weight ratio. Its lighter weight implies that less force is required to move the lorry, leading to greater fuel efficiency. Although aluminum is not the strongest metal, alloying it with other metals assists to increase its strength. Its corrosion resistance is an included bonus offer, getting rid of the requirement for heavy and pricey anti-corrosion coverings.

While the car industry still relies greatly on steel, the drive to increase fuel performance and lower CO2 emissions has actually caused a much broader use of aluminum. Professionals predict that the typical aluminum material in a vehicle will increase by 60% by 2025.

High-speed rail systems Maglev in Shanghai also utilize aluminum. The metal enables designers to minimize the weight of the trains, minimizing friction resistance.

Aluminum is also called the ‘winged metal’ due to the fact that it is perfect for aircraft; once again, due to being light, strong and versatile. In fact, aluminum was utilized in the frames of Zeppelin airships prior to planes having actually even been created. Today, modern-day aircraft usage aluminum alloys throughout, from the fuselage to the cockpit instruments. Even spacecraft, such as space shuttles, include 50% to 90% of aluminum alloys in their parts.

In addition to power lines and cables, aluminum is used in motors, home appliances, and power systems. Television antennae and satellite dishes, even some LED bulbs are made of aluminum.

Aluminum Can Recycling Link

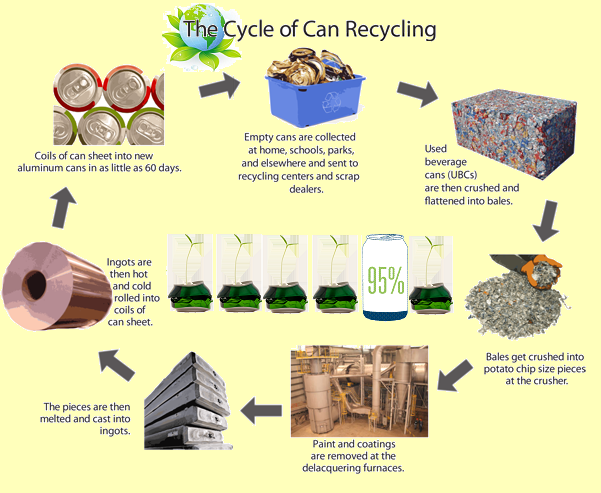

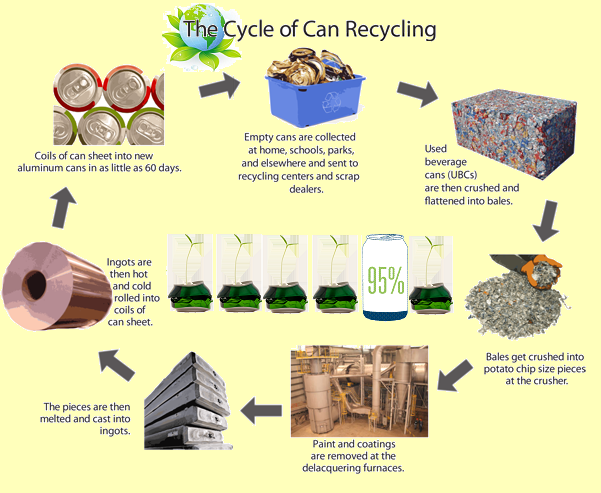

Aluminum seems to be one of the more common materials in the United States in which the public is reminded to recycle consistently. It’s a great material that can be reused and can create a closed loop system if recycled properly.The infographic above shows the lifecycle of an aluminum can from beginning to end.

In a nutshell the process of recycling an aluminum can goes as follows:

The consumer throws aluminium cans and foil into a recycle bin.

The aluminium is then collected and taken to a treatment plant.

In the treatment plant, the aluminium is sorted and cleaned ready for reprocessing.

It then goes through a re-melt process and turns into molten aluminium, this removes the coatings and inks that may be present on the aluminium.

The aluminium is then made into large blocks called ingots. Each ingot contains about 1.6 million drinks cans.

The ingots are sent to mills where they are rolled out, this gives the aluminium greater flexibility and strength.

This is then made into aluminium products such as cans, chocolate wrapping, and ready meal packaging.

In as little as 6 weeks, the recycled aluminium products are then sent back to the shops ready to be used again.

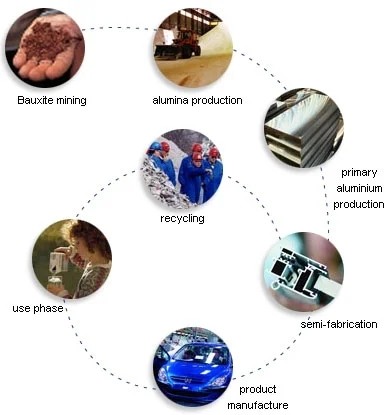

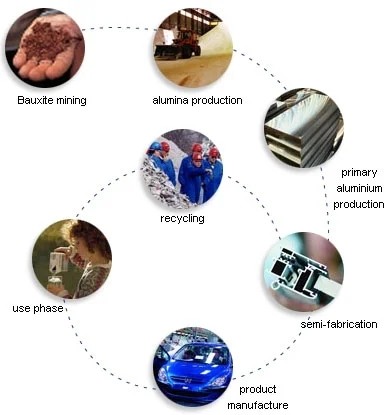

A “cradle to cradle” cycle of an aluminium product system can be modeled using different process steps as outlined in the flowchart below. It should be noted that “grave” relates here to the end of life of the product, not of the material aluminium since it is being recycled.

If you are a consumer of aluminum cans in your day-to-day life, please recycle the can or save it to recycle later if there aren’t any recycling locations nearby. It makes a great difference in how we continually use our resources from nature.

People's exploration of aluminum began with the study of alum in the 18th century.Alum is a general term for a class of compounds with similar properties, and the common alum in life is one of them.

As early as ancient Greece and Rome, people began to use alum. At that time, people used alum to stop bleeding, or as a dye to dye clothes. Research on alum showed that it contained an unknown element.

Bauxite Mining

The mining of bauxite is the first step in aluminium production.

At 8% of the earth’s crust, aluminium is the third most abundant element in nature.

The ore from which aluminium is produced is bauxite. Disregarding various quality grades, bauxite reserve estimates indicate adequate supply for at least 400 years. More than 130 million tonnes of bauxite are mined each year, the major deposits being in the tropics and sub-tropics. Bauxite is currently being extracted in Australia, Central and South America (Jamaica, Brazil, Surinam, Venezuela, and Guyana), Africa (Guinea), Asia (India, China), CIS, and parts of Europe (Greece and Hungary). In many of these regions, bauxite extraction is the only valuable natural resource.

Aluminum Application in Industries and Daily Life

Aluminum is the 3rd most plentiful metal in the Earth’s crust and the third most plentiful component total.

No other metal can compare to Aluminum when it concerns its variety of uses. Some uses of aluminum may not be instantly apparent; for example, did you know aluminum is utilized in the manufacturing of glass?

Aluminum is exceptionally popular due to the fact that it functions below:

Lightweight

Strong

Resistant to rust

Durable

Ductile

Malleable

Conductive

Odorless

Aluminum is utilized in transportation because of its unbeatable strength to weight ratio. Its lighter weight implies that less force is required to move the lorry, leading to greater fuel efficiency. Although aluminum is not the strongest metal, alloying it with other metals assists to increase its strength. Its corrosion resistance is an included bonus offer, getting rid of the requirement for heavy and pricey anti-corrosion coverings.

While the car industry still relies greatly on steel, the drive to increase fuel performance and lower CO2 emissions has actually caused a much broader use of aluminum. Professionals predict that the typical aluminum material in a vehicle will increase by 60% by 2025.

High-speed rail systems Maglev in Shanghai also utilize aluminum. The metal enables designers to minimize the weight of the trains, minimizing friction resistance.

Aluminum is also called the ‘winged metal’ due to the fact that it is perfect for aircraft; once again, due to being light, strong and versatile. In fact, aluminum was utilized in the frames of Zeppelin airships prior to planes having actually even been created. Today, modern-day aircraft usage aluminum alloys throughout, from the fuselage to the cockpit instruments. Even spacecraft, such as space shuttles, include 50% to 90% of aluminum alloys in their parts.

In addition to power lines and cables, aluminum is used in motors, home appliances, and power systems. Television antennae and satellite dishes, even some LED bulbs are made of aluminum.

Aluminum Can Recycling Link

Aluminum seems to be one of the more common materials in the United States in which the public is reminded to recycle consistently. It’s a great material that can be reused and can create a closed loop system if recycled properly.The infographic above shows the lifecycle of an aluminum can from beginning to end.

In a nutshell the process of recycling an aluminum can goes as follows:

The consumer throws aluminium cans and foil into a recycle bin.

The aluminium is then collected and taken to a treatment plant.

In the treatment plant, the aluminium is sorted and cleaned ready for reprocessing.

It then goes through a re-melt process and turns into molten aluminium, this removes the coatings and inks that may be present on the aluminium.

The aluminium is then made into large blocks called ingots. Each ingot contains about 1.6 million drinks cans.

The ingots are sent to mills where they are rolled out, this gives the aluminium greater flexibility and strength.

This is then made into aluminium products such as cans, chocolate wrapping, and ready meal packaging.

In as little as 6 weeks, the recycled aluminium products are then sent back to the shops ready to be used again.

A “cradle to cradle” cycle of an aluminium product system can be modeled using different process steps as outlined in the flowchart below. It should be noted that “grave” relates here to the end of life of the product, not of the material aluminium since it is being recycled.

If you are a consumer of aluminum cans in your day-to-day life, please recycle the can or save it to recycle later if there aren’t any recycling locations nearby. It makes a great difference in how we continually use our resources from nature.