Several Factors that Affect Magnet Pull Force

Introduction

Magnets can generate magnetic fields and can pull ferromagnetic materials. Because of this feature, magnets are applied to various areas of our lives. The pull force of magnets is the basis of many applications. This article will focus on how to increase the pull force from several factors that affect the pull force of magnets, so as to meet the design requirements of the application.

The pull force of the magnet is mainly determined by its own performance, size, structure and shape of the magnet, and also determined by other metal parts. First, the performance of the magnet, which is exactly the material properties of the magnet itself. Magnets are divided into hard magnetism and soft magnetism. Among them, the strongest magnetism is the neodymium iron boron magnet in the hard magnetism, and its magnetic energy product can reach 57MGOe.

Generally speaking, the magnetic force in hard magnets is arranged in the order of from small to large: Ferrite-AlNiCo-SmCo-NdFeB. According to the application requirements, we can choose the corresponding magnet material. Ferrite materials are cheap, but their performance is low, and cannot meet many application requirements. Compared with ferrite, AlNiCo has improved performance and has good temperature characteristics. It can withstand high temperatures of 550°C, but because of its low coercivity, it has weak resistance to demagnetization. The magnetic force of SmCo magnet is relatively close to that of NdFeB, but because of its high hardness and brittleness of the material, it is easily broken during use. Although NdFeB has high relative material price, its excellent magnetic properties can make up for it.

The effect of grade on magnet pull force

Choose a kind of magnet, as the material grade increases, how does the pull force change? Choose a standard size D10X10 with axial magnetization as an example. Assume its material grade ranges from N35 to N55. From the figure below, it can be find that the pull force of the magnet on the iron plate is proportional to the material performance level, but the increase in the magnetic force is not too obvious. Therefore, when designing a product, upgrading one or two material grade levels does not bring about a greater improvement effect.

The effect of size on magnet pull force

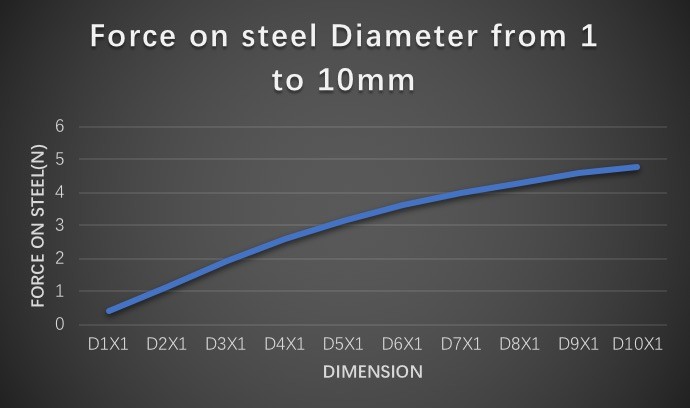

In terms of material selection, in general, the larger the size, the greater the pull force, but the growth of the pull force is greatly affected by the shape of the product, that is, the ratio of height to diameter.For instance, N40 NdFeB magnet with axial magnetization, as shown in figure left below. When the height of the magnet is fixed to 1mm and the diameter of the magnet gradually increases from D1 to D10, the pull force increases with the diameter. There is an obvious linear relationship.

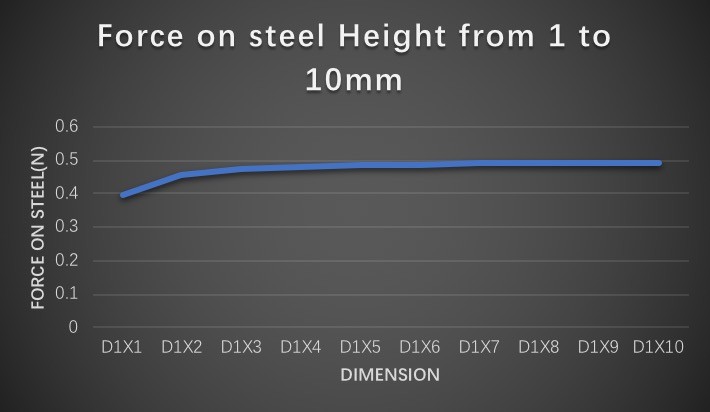

As shown in figure right below, when the fixed diameter is D1, and the magnet height increases from 1mm to 10mm, the way the pull force grows is different. Between the height of 1mm and 3mm, the growth rate of pull force is relatively large. However, though the size of magnet is increasing, the growth rate slows down and the pull force levels off. With the two curves, the following rules can be found:

1. The increase of a magnet's pull force is directly proportional to the volume of the magnet.

2. The diameter of a magnet has a great influence on its pull force, and the relationship is linear.

3 When the diameter is constant, and the height of the magnet reaches to a certain level, the pull force almost does not increase.

Therefore, when designing magnetic adsorption products, if you want to obtain a stronger pull force, you need to increase the diameter. In another word, increasing the adsorption area is a way to achieve the wanted design.

The effect of metal permeable objects on magnet pull force

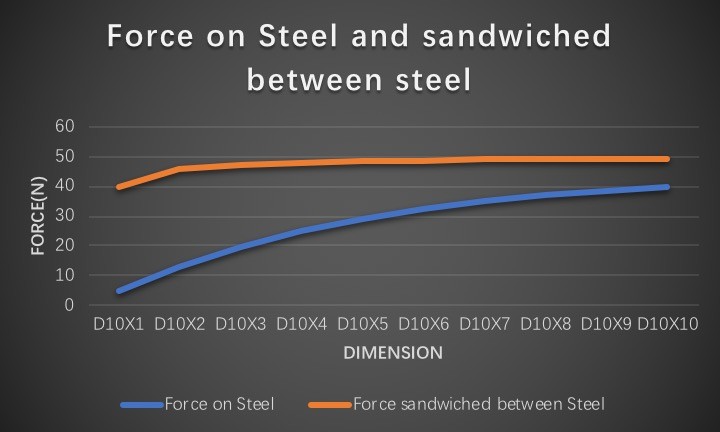

In addition to the properties of the material itself and the adjustment of the size and shape can increase the pull force of the magnet, it can also change the magnetic field structure of the magnet itself by adding metal permeable objects to achieve the purpose of increasing the magnetic force. For example, a piece of metal permeable material is adsorbed on one of the pole faces of the magnet, so that the lines of magnetic force are offset in one direction, so as to maximize the magnetic force of the adsorption face. According to the below gif, it can be seen that the addition of iron sheets can greatly increase the pull force, which is particularly effective for products with relatively thin thickness.

Conclusion

The performance of magnet material determines the basis of pull force. By adjusting the size structure of magnet and improving the structure of magnetic force line, the pull force of magnet can be greatly improved under the premise of controlling the cost.