Different Types of Screw Threads and Terminology

In magnet application, screws are frequently seen. A typicl example is pot magnet. And today we'd like to have a deeper look into different type of screw.

From professional contractors to the DIYers at home, virtually every individual performing a construction, remodeling or decorating project will use screws and fasteners. These small tools come in many shapes and sizes, typically labeled using terminology that the average homeowner or novice repair servicer may not be familiar with.

Learning and memorizing the different types of screw threads can be confusing. To help you identify the type and use of various screws, we've created this helpful screw thread terminology guide that you can quickly reference any time you need to select a specific screw and screw thread measurement.

What Are the Different Types of Screws?

If you've ever felt lost walking down the fastener aisle of the hardware store, you're not alone. The types of screws you need for a woodworking project like building a table are different from the screw types and sizes you would use when building a deck. Refer to our list of the different types of screws to help you identify which is the right fastener for your job:

Woodworking

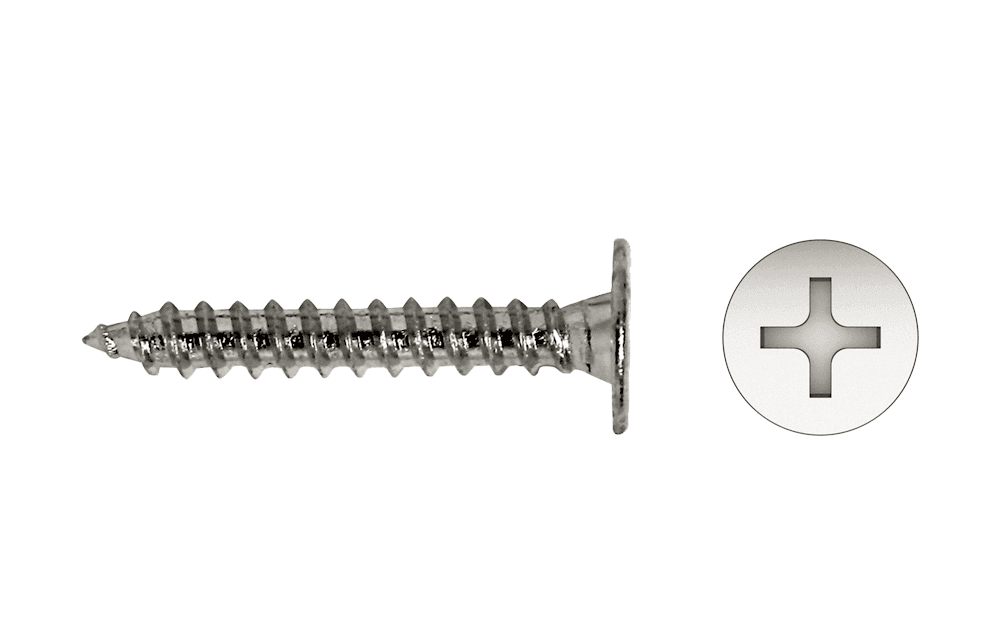

Woodworking screws are some of the most common types of screws. Used for connecting two or more wooden objects, woodworking screws feature a tapered shank with sharp threading to dig into the wood.

Drywall

Although they can be used for woodworking, drywall screws are designed for use on drywall projects. However, the wrong-sized drywall anchor screw could damage pure plaster walls. The drywall screw size, length and weight must match the type of wall or ceiling drywall being used. Many drywall screws as twinfast screws which feature two threads.

Machine

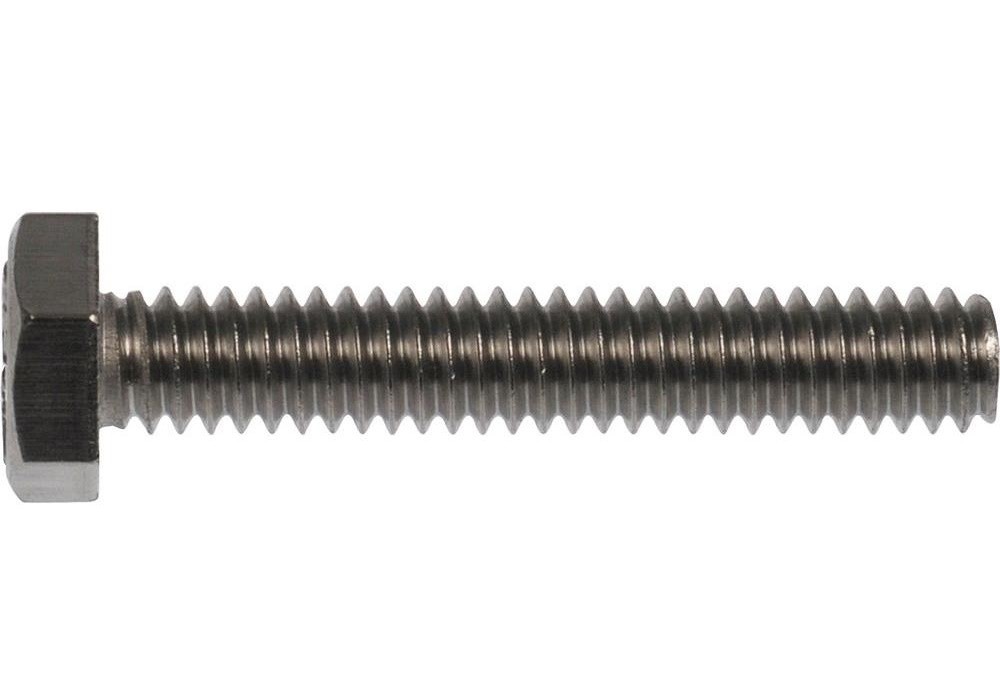

Similar to woodworking screws, machine screws are a common type of screw used in machining applications to connect two or more metal objects.

Lag

Also known as coach screws, a lab screw is a type of screw that forms its own thread in pre-drilled holes and is usually used to fasten metal to wood.

Gutters and siding

Screws used for gutters and siding are designed to provide a stronger hold, typically coated with a weather-resistant material and available in finishes to match the gutter or siding color.

Security

Security screws are unique in that they do not have an operable head like other screws, which protects them from being removed or tampered with. To install or remove these screws, special tools are required.

Self-drilling

Self-drilling screws are available as “magnetic” and “non-magnetic” stainless steel varieties that are used for metal-to-metal and wood-to-metal applications. Roofing screws are an example of self-drilling screws.

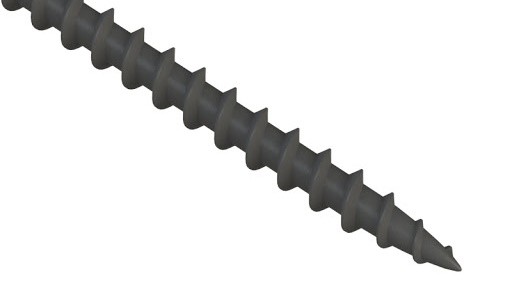

Self-piercing

Self-piercing screws have powerful penetration capabilities because their threads are machined down to the end of the point.

Self-tapping

Self-tapping screws are threaded to create their own holes when installed. They form a matching thread in whatever material they are installed into. Self-tapping screws like sheet metal screws may be used in HVAC applications. Self-tapping deck screws are often coated with a corrosive-resistant material, such as ceramic.

Thread-forming

Used with plastic materials, thread-forming screws feature two separate threads: one high and one low. This makes the pullout strength higher while also ensuring plastic does not crack or otherwise break.

Type U

Type U screws have a unique spiral thread, and they are typically fastened into a plastic or metal casing material via a hammer instead of a screwdriver.

Screw Thread Terminology

Knowing the different screw types and sizes is helpful, but to accurately select the right screw for your project, you’ll likely need to know a little about how screw threads work, as well. So, how do screw threads work? Like the screws themselves, screw threads are designed to meet the needs of specific applications.

Types of screw threads

You can try to find a screw thread chart that outlines all of your different options, but what you really need is a guide to screw thread terminology that answers all your questions and provides a comprehensive rundown of different screw and bolt thread types and why they matter.

To help you make the best investments in fasteners for your next project, here's a thorough guide to screw thread terminology:

External Threads

External threads (ie: male threads) mean the threads are on the bolts or screws. Threads are sometimes on the nuts rather than the bolts or screws.

Internal Threads

Internal threads (ie: female threads) mean the threads are on the nuts rather than the bolts or screws.

Machine Screw Threads

Machine screw threads are unique in that they are specially designed to mate with threads on nuts or threads present in tapped holes. Not self-tapping threads.

Spaced Threads

Spaced threads are designed to form their own threads in pre-drilled holes. You’ll most often find spaced threads on self-tapping, wood and coach screws.

Lag Screws

Lag screws are just one example of screws that form their own thread in pre-drilled holes. Typically, coach screws are used to fasten metal to wood.

Self-Tapping Screws

Self-tapping screws are threaded to create their own holes when installed. They form a matching thread in whatever material they are installed into. This makes using self-tapping screws incredibly efficient.

Thread-Forming Screws

Used with plastic materials, thread-forming screws feature two separate threads: one high and one low. This makes the pullout strength higher while also ensuring plastic does not crack or otherwise break.

Type U Screws

Type U screws include an unusual spiral thread that is most often driven with a hammer into materials like plastic and metal casings.

Wood Screws

Wood screws feature a tapered shank with sharp threading.

Additional Fastener Terminology

Here are a few additional terms related screws and threading that are helpful to know:

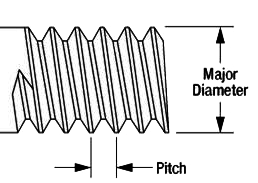

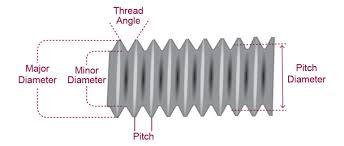

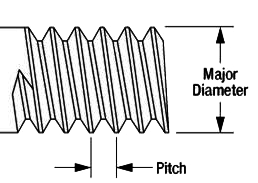

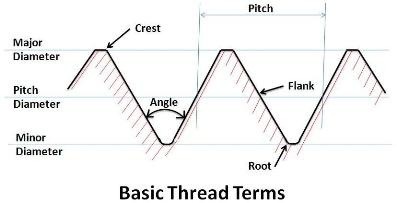

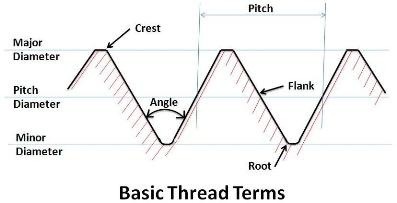

Major Diameter

This refers to the diameter of a screw including the raised helix’s height. Measure using a slot gauge or a caliper rule. You can only measure major diameter with an external thread screw

Minor Diameter

Minor diameter is a screw’s diameter measured at the base or root of the thread at the innermost part of the screw. You need specialized equipment to measure the minor diameter accurately.

Effective Diameter

The effective diameter is essentially the average of the major and minor diameters. It is measured halfway up the raised helix, and, again, you need specialized equipment to get an accurate sense of a screw’s effective diameter.

Pitch

The pitch is the distance between two threads on the same screw.

Crest

The crest is the height of an external thread. Or, you can find the crest by subtracting minor diameter from major diameter. The crest is the difference between the two.

Thread angles

The thread angle is the actual angle of both flanks of a screw. Symmetrical threads indicate that both sides of the thread are angled to the same degree. It’s common for thread angles to be referred to as simply “the flank.”

Above are the introduction our screw threads and its terminology. Feel free to discuss with us.