What is a magnetic polishing machine and what is the principle of a magnetic polishing machine?

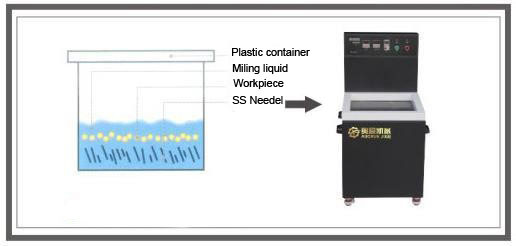

Magnetic polishing machine is also

called magnetic tumbler. This polishing equipment breaks through the

traditional vibration grinding and polishing concept. It uses magnetic force to

drag the stainless steel needle grinding material to produce rapid rotational

motion, thereby achieving multiple effects such as burr removal, polishing, and

cleaning. Utilizing its unique magnetic field distribution to produce a strong

and stable magnetic induction effect, the magnetic steel needle and the

workpiece are fully ground in all directions and at multiple angles to achieve

rapid rust removal, dead corners, burr removal, oxide film and sintering

traces. and other effects. Especially for workpieces with complex shapes,

porous gaps, internal and external threads, etc., it can show its magical

effect. It does not damage the surface of the workpiece and does not affect the

accuracy of the workpiece. Make the workpiece instantly smooth, tidy and brand

new. Suitable for grinding and polishing gold, silver, copper, aluminum, zinc,

magnesium, iron, stainless steel and other metals and non-metallic workpieces

such as hard plastics. After being processed by this type of polishing machine,

the surface of the workpiece will show the original metallic luster, which is

bright and round and has a visual effect; it can also release part of the

internal stress of the workpiece and improve the mechanical properties of the

workpiece; strengthen the surface quality of the workpiece and improve the

surface performance.

Features of magnetic polishing machine

1. Achieve multiple functions such as

deburring, chamfering, polishing, and cleaning;

2. For irregular-shaped parts, dead

corners such as holes and tubes, and cracks can be polished without any dead

corners;

3. The equipment can set the time, the

processing speed is fast, the operation is simple and safe, the end reminder

can remind the polishing to be completed, and one person can operate multiple

machines; the polishing process does not require manual intervention;

4. Variable frequency adjustment to meet

various polishing needs. Stainless steel needles are available in different

diameters from 0.2-5MM to 1.2-10MM;

5. After grinding, the workpiece will

never be deformed, the surface will not be damaged, the accuracy will not be

affected, and the shape and size will not change. The surface roughness value

can reach Ra0.1-Ra0.01, and the surface shows bright metallic luster;

6. Low cost, the grinding time is about

2-20 minutes to complete; the operation is simple, convenient, completely

technology-free, and can be operated by multiple machines;

Application scope of magnetic polishing machine

Suitable for grinding and polishing

gold, silver, copper, aluminum, zinc, magnesium, titanium, stainless steel and

other metals and non-metallic workpieces such as hard plastics.

Such as: 1. Precision stamping parts; 2.

Stainless steel, copper and other metal parts, screw threads; 3. Magnesium

aluminum die-cast parts;

4. Zinc and aluminum die-cast parts; 5.

Precision spring and spring parts; 6. Electronic, computer, and communication

parts;

7. Centering, tooling, CNC automatic

lathe parts; 8. Mobile phone casing, communication metal casing

Disadvantages of magnetic polishing machine:

1. The consumables are the martensite

stainless steel needle and the grinding fluid used;

2. The current and voltage required for

work are relatively large, which can easily cause safety hazards;

3. Power consumption is fast, machine

parts wear out quickly, and maintenance costs are relatively high;