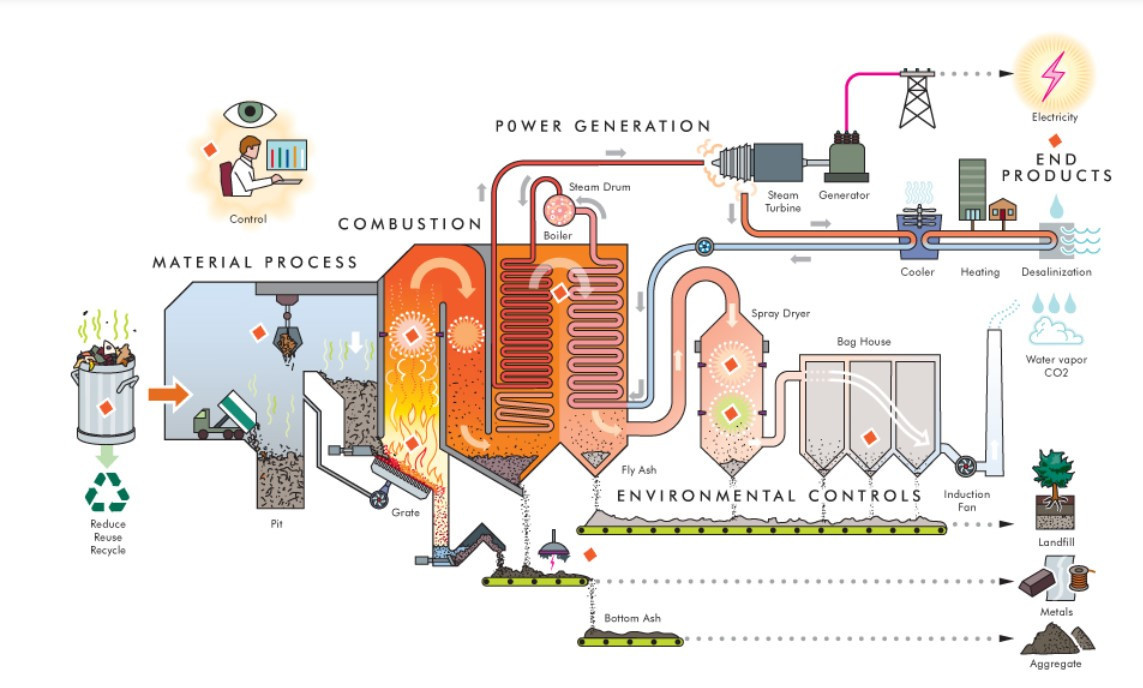

How waste-to-energy incineration works

Waste-to-energy plants use household garbage as a fuel for generating power, much like other power stations use coal, oil or natural gas.

Regarding garbage incineration, the first thing to note is that not all garbage can be burned. In general, garbage incineration is the burning of organic components in waste. For example, municipal solid waste represented by various domestic wastes including kitchen waste can kill toxic and harmful components through incineration, and greatly reduce the volume of waste. It can also be used, and the landfill after burning saves space. The calorific value released during combustion can also be used to generate electricity and heat, and become a waste-to-energy source.

The biggest concern of environmentalists and the public about waste incineration comes from the emission of toxic substances such as dioxins and furans during the incineration process. In the last century, the old-fashioned incinerators of various countries did not pass the gas purification technology, and this problem did exist. Since the end of the last century, many countries have improved gas purification technology and hardware, and the situation has improved greatly.

Waste-to-Energy: How It Works

Waste material is received in an enclosed receiving area, where it is thoroughly mixed in preparation for combustion.

The mixed waste enters the combustion chamber through the grate that moves regularly, and the grate splashes and burns at the same time.

The particles in the air are removed in the filter bag.The acidic combustion gas is neutralized by injecting lime or sodium hydroxide.Acid combustion gas injection lime or sodium hydroxide to neutralize.

The unburned residue from the combustion is removed by magnets and eddy current separators to remove iron and other metals such as copper, brass, nickel and aluminum for recycling.The unburned residue from the combustion is removed by magnets and eddy current separators to remove iron and other metals such as copper, brass, nickel and aluminum for recycling.

Combustion of unburned residues, remove iron and other metals, such as copper, brass, nickel and aluminum by a magnet and the vortex separator for recycling.

The remaining ash can be used as aggregate for roadbeds and railway embankments.

Superheated steam powers the steam turbine generator. The cooling steam is cycled back into water through the condensor or diverted as a heat source for buildings or industry. Cooled stream is reheated in the economiser and superheater to complete the steam cycle.